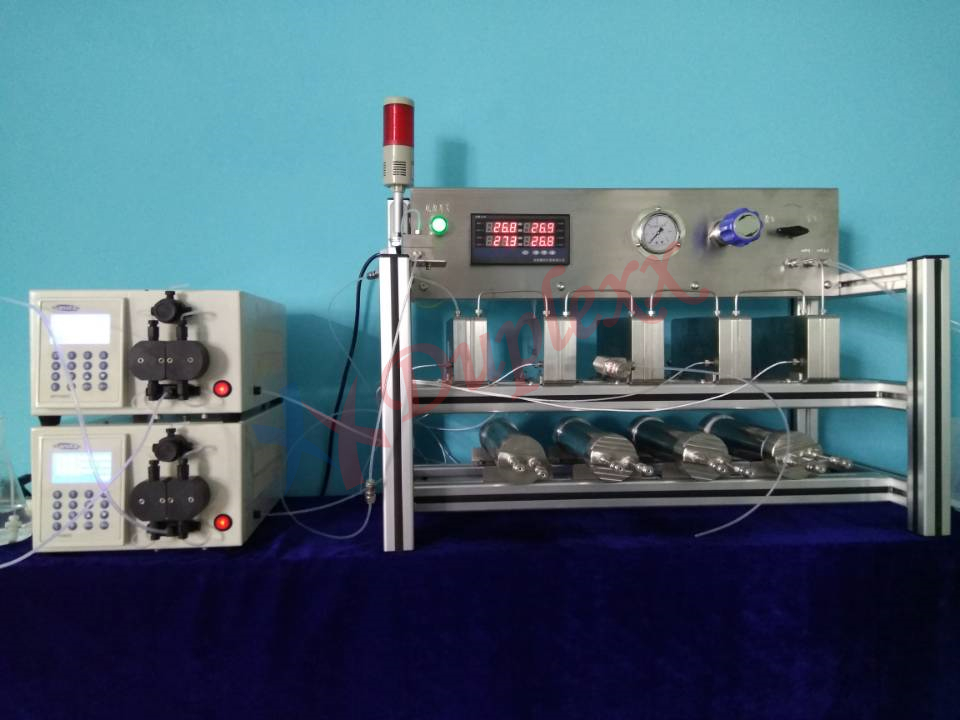

Multifunctional Microreactor Platform

Release time:2019-09-30 12:00:01

The multi-functional micro-reaction complete set is a complete set of experimental reaction system designed and developed by Kunshan Fuxi Engineering Technology Co., Ltd. according to the characteristics of micro-channel reaction. It integrates various factors such as reaction temperature, reaction pressure and residence time. In two-phase, multi-phase, gas-liquid, liquid-liquid, homogeneous and heterogeneous, endothermic and strong exothermic reactions.

Compared with the traditional experimental equipment, the system equipment has high modularity, simple structure, convenient operation, safety and reliability, real-time monitoring, rapid realization of various switching combinations, different experimental conditions, and rapid screening and optimization of process conditions. Accelerate the progress of the experiment, improve the experimental results, and provide accurate experimental data for subsequent pilot and industrialized continuous production.

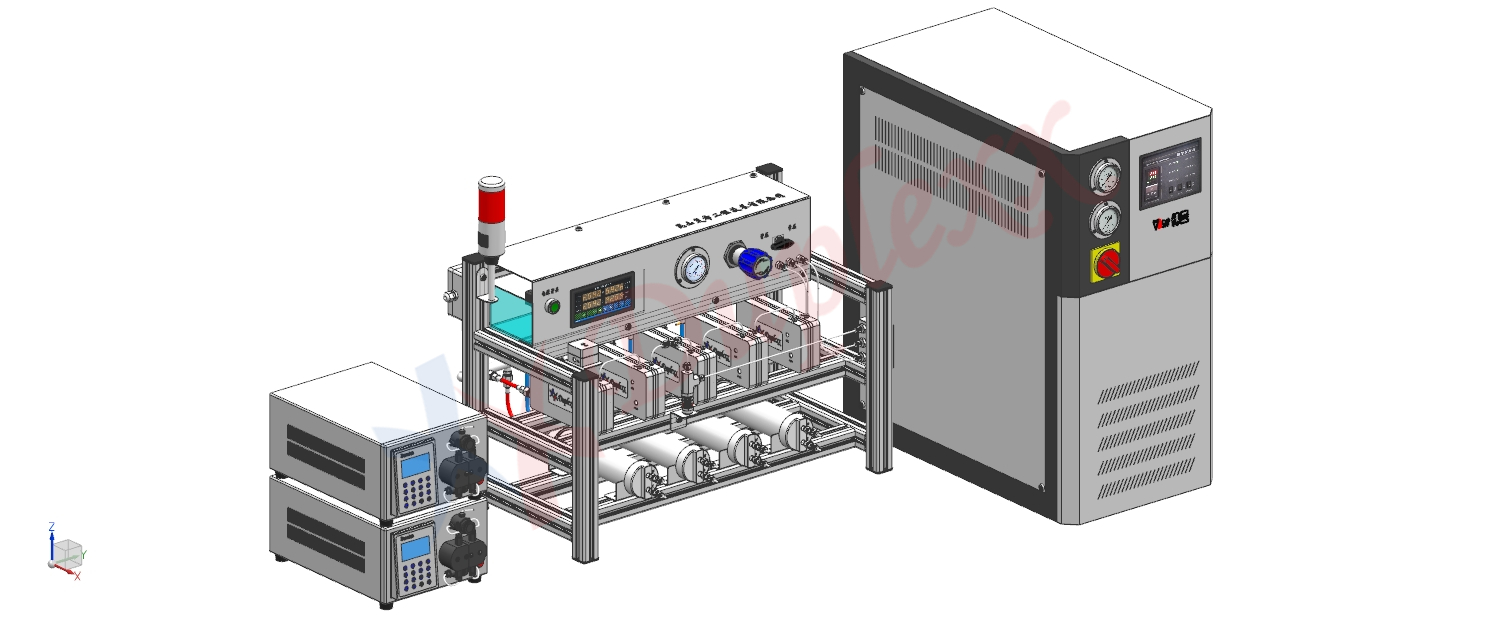

2. Microreactor complete device structure description

The microreactor complete set is divided into different functional areas such as feed control, preheating and delay, strong mixed micro-mixing module, mixed reaction micro-reaction module, system control, multi-functional discharge, etc., integrated in high-strength aluminum alloy frame structure. within.

2.1 Feed control

The feed control section includes a gas phase inlet and two to three liquid phase inlets for gas-liquid, liquid-liquid two-phase and gas-liquid-liquid, liquid-liquid-liquid three-phase feed.

2.2 Preheating and delay

The unit integrates four tubular reactor modules for heat exchange and extended reaction residence time. The preheating of the reaction medium and the delay of the reaction product can be completed, and the temperature of the reaction medium and the residence time of the reaction product can be better controlled, and the optimal reaction effect and product quality can be obtained.

2.3 Powerful hybrid micro-hybrid module

The device integrates a micro-mixer module (available in many different formats). Micromixers refer to collisions of fluids in specially designed microchannels on the order of hundreds of microns, enabling instantaneous uniform mixing of materials.

2.4 mixed reaction microreaction module

The device integrates 5 microreactor modules (1~5 blocks can be selected according to the reaction conditions). Microreactor refers to the collision of fluids in channels with sub-micron to millimeter scale and special mixed shape, which can achieve continuous mixing and reaction of heterogeneous materials; wall-to-wall heat transfer, contact temperature probe, real-time feedback of reaction conditions Get response data in a timely manner.

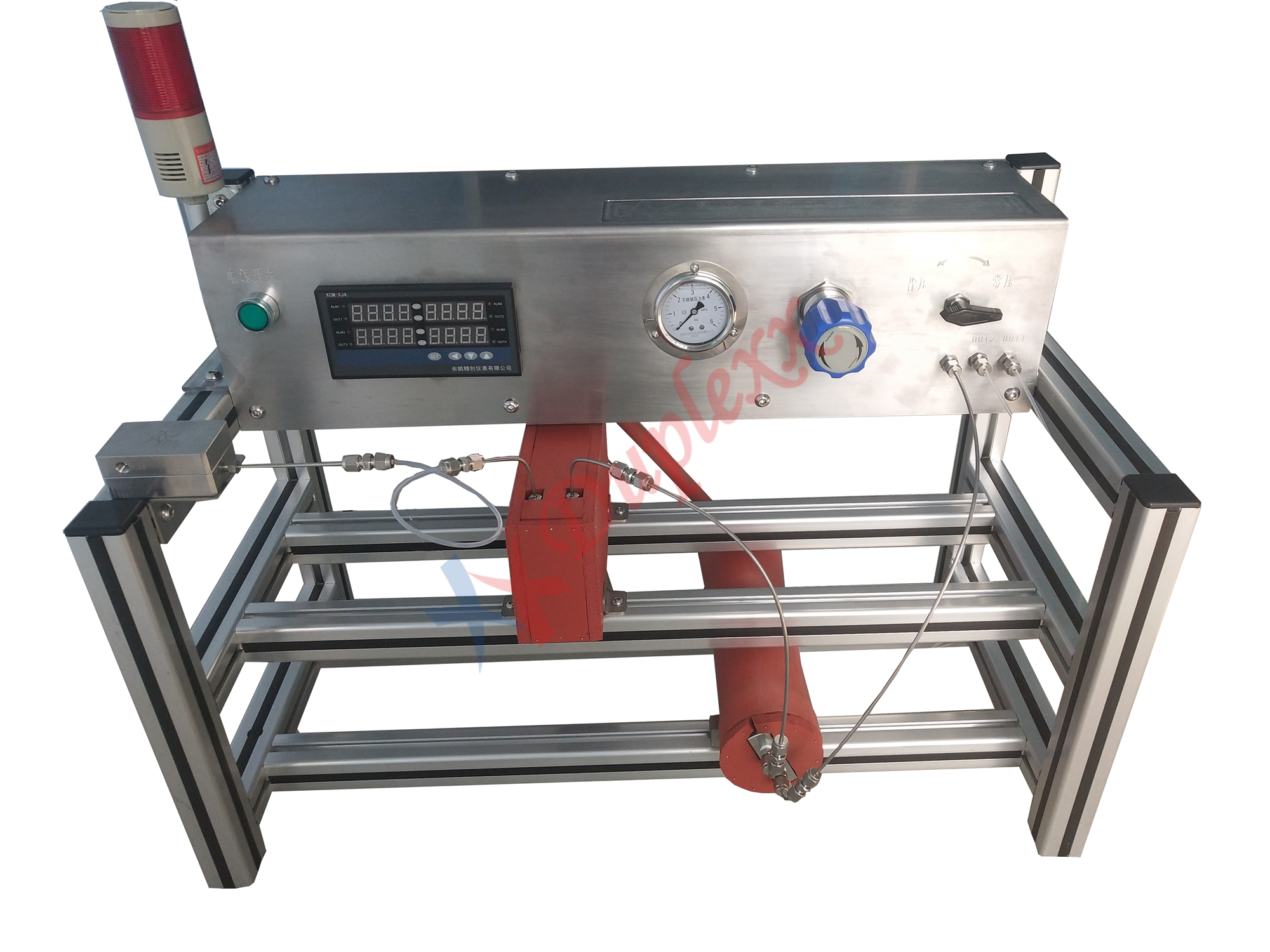

2.5 System Control

The device integrates alarm system, one-button start, four-channel temperature display, back pressure valve, pressure gauge, real-time monitoring of reaction temperature and pressure; over-temperature, over-pressure and other alarm systems ensure safety.

2.6 Multi-functional discharge

The three-way valve with three discharge ports and discharge switching can complete the operation of mid-sampling, control system reaction pressure conditions, and extended residence time.

中文简体

中文简体 ENGLISH

ENGLISH