Alumina (γ-Al2O3) Microspheres

Release time:2019-10-09 17:04:36

Product use: catalyst, catalyst carrier, gas and liquid desiccant, gas purification adsorbent, drinking water defluoridation agent, industrial sewage color and odor eliminating agent.

Existing preparation techniques and problems: The existing alumina microsphere preparation process is as follows:

| raw material | Disadvantage | |

| 1、Spray drying | Mixture of alumina powder and aluminum sol | Uniform particle distribution, single product |

| 2、Rolling ball | Mixture of alumina powder and aluminum sol | Large particle size, single product |

| 3、Oil column forming |

a mixture of aluminum sol and gelling agent,

An organic amine is dissolved in the oil column as an auxiliary gelling agent.

|

Severe energy consumption, ammonia corrosion equipment generated in the process, single product |

The present technology and features: The technology uses an industrial grade aluminum sol as an aluminum source, and uses a special curing agent (about 10 wt%) to prepare alumina microspheres using a microfluidic molding technique.

The technical features are:

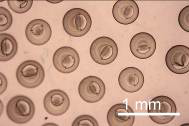

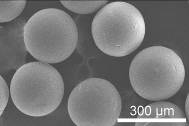

Product microsphere size is uniform

High product packing density

Production can be adjusted flexibly

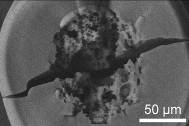

Can prepare a variety of microspheres from solid to hollow

Microsphere size can be adjusted between 50 microns and 2 mm by process parameters and microfluidic device channel size

Performance comparison between industrial alumina microspheres and alumina microspheres prepared by this process

| index | Industrial alumina microspheres | Alumina microspheres prepared by the present technology |

| Particle size mm | 0.5 ~ 10 | 0.05 ~ 10 |

| Kong Rong cm3/g | 0.35 ~ 0.4 | 0.4 ~ 0.7 |

| Aperture nm | ---- | 9 ~ 15 |

| Specific surface area m2/g | 150 ~ 300 | 160 ~ 180 |

| Bulk density g/cm3 | 0.5 ~ 0.7 | 0.9 ~ 0.95 |

| Hollow microsphere | Solid microsphere | |

|

|

|

中文简体

中文简体 ENGLISH

ENGLISH