Nano Barium Sulfate(BaSO4)

Release time:2019-10-09 17:00:45

Product use: used as raw materials or fillers for paints, inks, plastics, rubber and batteries, surface coating agents for printing paper and copper paper, sizing agents for textile industry. It can also be used as a clarifying agent in glass products, which can act as defoaming and increase gloss. It can be used as a protective wallpaper for radiation protection. It is also a raw material for the manufacture of other barium salts. It can also be used as a digestive system contrast agent in medical treatment. High-purity nano-barium sulphate has a wide range of applications in the industrial sectors such as coatings, paper, rubber, ink, and plastics. The barium sulfate product having an average particle diameter of 0.2 μm can be effectively used as a dispersing agent in a colored pigment because of its good dispersibility, so that the color tone of the coating, printing, ink and the like is more vivid and more lustrous.

Existing processes and problems: The existing barium sulfate production is mostly carried out by using the Glauber's salt-black ash method, the clarified and filtered Glauber's salt water and the sputum water, and the reaction is added to the chemical tank at a certain ratio, and the obtained product is ordinary barium sulfate. The average particle diameter is about 10 μm; in 1995, a fine barium sulfate having an average particle diameter of about 0.2 μm was prepared by reacting barium sulfide and a sulfuric acid solution in a reaction tank in 1995. In summary, the powder particles obtained by the prior art barium sulfate powder preparation technology have large particle size, wide particle size distribution, irregular morphology, and poor repeatability between batches. There are few techniques for preparing nanometer barium sulfate powder having a particle diameter of less than 100 nm.

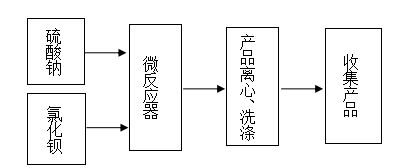

The present technology and features: The present technology utilizes a method of directly precipitating ruthenium chloride and sodium sulfate to prepare nano-barium sulfate having a maximum particle diameter of 100 nm or less in a microstructure reactor.

(1) It can be carried out at room temperature, the reaction time is short, continuous operation, and the process is clean.

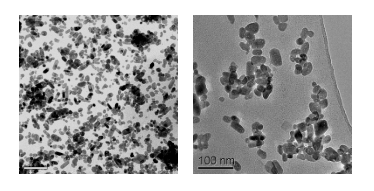

(2) The product is an ellipsoidal or rod-shaped particle and is a high-purity polycrystalline structure.

(3) A product having a particle size distribution of 13-86 nm, an average particle diameter of 38 nm (left), a particle size distribution of 14-58 nm, and an average particle diameter of 29 nm (right) was obtained by the process parameters. The particle size distribution is narrow.

中文简体

中文简体 ENGLISH

ENGLISH