Continuous Synthesis of Antibacterial

Release time:2019-10-09 17:31:18

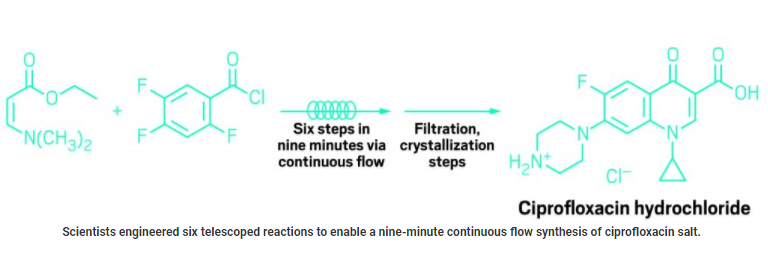

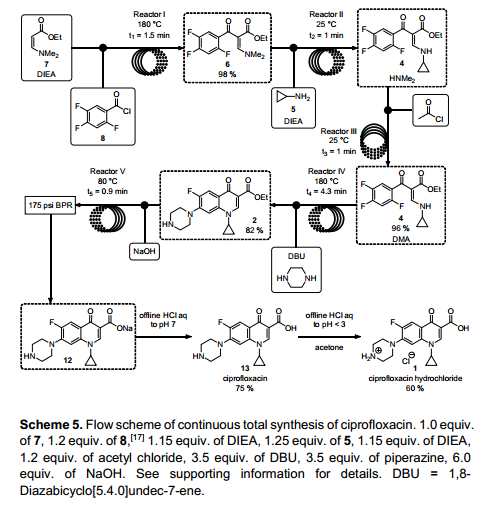

On August 24th, Tien Nguyen reported from the American Chemical Society Annual Meeting Washington DC: MIT successfully implemented continuous synthesis of antibiotic-ciprofloxacin. The whole synthesis process requires 6 steps including filtration and crystallization, but only 9 minutes in total ( The traditional kettle process requires more than 100 hours), and the total yield of the full continuous process is comparable to that of the conventional process (about 60%). This is said to be the longest fully continuous flow full synthesis case ever achieved (Angew. Chem.Int. Ed. 2017, DOI: 10.1002/anie.201703812).

Flow chemistry allows chemists to synthesize new molecules quickly and efficiently through a series of reactions and separations, but as each step increases, the process becomes more challenging: the solubility of intermediate compounds and the reaction The by-products produced may cause blockage of the reactor piping.

[Editor: This case shows that many seemingly impossible continuous flow processes can overcome challenges and enter new realms through "smart efforts." 】

At present, it takes more than 100 hours to produce ciprofloxacin in the traditional reactor gap, and the total yield is about 60%. According to Professor Timothy Jamison of the Massachusetts Institute of Technology (MIT), his team worked with the laboratory of Professor Klavs Jensen of MIT to develop a fully continuous synthesis process of ciprofloxacin in just 9 minutes, with a total yield of about 60%.

Hongkun LIN, a postdoctoral researcher at Klavs Jensen's lab, disclosed the results earlier this week at the American Chemical Society's annual meeting of the Organic Chemistry Poster Conference in Washington DC.

Early in the postdoctoral work of Professor Klavs Jensen's laboratory, Christopher Smith, an organic chemist at Reading University, also praised the example of how to overcome the problems in mobile chemistry during the development of this new process. For example, the research team solved the problem of low solubility in multiple intermediate reaction steps by screening multiple solvent systems and heating the system to 180 ° C and then rapidly cooling back to room temperature.

Timothy Noël of Eindhoven University of Technology, also deputy editor of the journal Mobile Chemistry, also praised the team's one-step reaction to the by-product amination, which led to the acid chloride being wisely reacted, thereby reacting by-product aminations. The overall response proceeded smoothly.

[Editor: Continuous Flow Chemistry provides a new platform for synthesis, which requires chemical synthesis personnel to jump out of the traditional kettle-type intermittent synthesis ideas, but also brings new challenges to everyone, and needs our wisdom and innovation to make breakthroughs]

Noël adds that the advantage of continuous-flow chemical synthesis is the ability to continuously produce products using very compact integrated equipment, while traditional batch reactor processes require complex and expensive production plants.

中文简体

中文简体 ENGLISH

ENGLISH